Warning: count(): Parameter must be an array or an object that implements Countable in /home1/exhausthooddepot/public_html/wp-content/themes/envision/cloudfw/core/engine.skin/core.skin_engine.php on line 1453

Warning: count(): Parameter must be an array or an object that implements Countable in /home1/exhausthooddepot/public_html/wp-content/themes/envision/cloudfw/core/engine.skin/core.skin_engine.php on line 1453

Warning: count(): Parameter must be an array or an object that implements Countable in /home1/exhausthooddepot/public_html/wp-content/themes/envision/cloudfw/core/engine.skin/core.skin_engine.php on line 1453

Warning: count(): Parameter must be an array or an object that implements Countable in /home1/exhausthooddepot/public_html/wp-content/themes/envision/cloudfw/core/engine.skin/core.skin_engine.php on line 1453

Warning: count(): Parameter must be an array or an object that implements Countable in /home1/exhausthooddepot/public_html/wp-content/themes/envision/cloudfw/core/engine.skin/core.skin_engine.php on line 1453

Warning: count(): Parameter must be an array or an object that implements Countable in /home1/exhausthooddepot/public_html/wp-content/themes/envision/cloudfw/core/engine.skin/core.skin_engine.php on line 1453

Warning: count(): Parameter must be an array or an object that implements Countable in /home1/exhausthooddepot/public_html/wp-content/themes/envision/cloudfw/core/engine.skin/core.skin_engine.php on line 1453

Warning: count(): Parameter must be an array or an object that implements Countable in /home1/exhausthooddepot/public_html/wp-content/themes/envision/cloudfw/core/engine.skin/core.skin_engine.php on line 1453

Warning: count(): Parameter must be an array or an object that implements Countable in /home1/exhausthooddepot/public_html/wp-content/themes/envision/cloudfw/core/engine.skin/core.skin_engine.php on line 1453

Warning: count(): Parameter must be an array or an object that implements Countable in /home1/exhausthooddepot/public_html/wp-content/themes/envision/cloudfw/core/engine.skin/core.skin_engine.php on line 1453

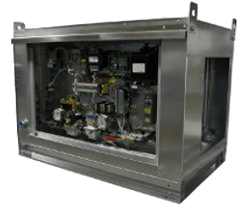

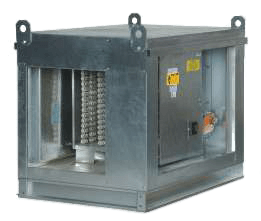

DIRECT FIRED MODULE

Direct Gas-Fired Heater Module, for use in tempering make up air. Direct fired modular heaters are designed for natural or propane gas applications. Heaters are rated for indoor or outdoor installations in commercial occupancies. A unique feature is the self-adjusting burner profile plates allowing 2-speed and variable-air-volume applications. The plates ensure proper air velocity and pressure drop across the burner for clean combustion. Spring loaded profile plates react to the momentum of the fresh air stream, therefore, no motors or actuators are needed to drive them. Nor do they need to be manually set to a specific position.

Packages start at 1000 CFM and go up to 21,000 CFM, with external pressures up to 2″ WG. Units have large doors on both sides to provide ample access to all internal components. Direct fired module consist of galvanized enclosure control panel and stainless steel burner.

FEATURES & BENEFITS

- G90 galvanized construction.

- Easy access doors.

- Lifting points.

- Redundant gas values.

- Pre-wired, pre-piped controls.

- Horizontal or down discharge.

- Fully insulated casing.

- Stainless steel burner.

- Intermittent spark pilot with timed safety lockout.

- Electronic flame modulation.

- High temperature limit switch.

- Airflow proving switch.

- Economizer inlet thermostat.

- Burner observation port.

HOT WATER COIL

Heating applications are most commonly used in hot fluid systems for comfort conditioning of a forced air stream and in process systems for drying processes. The collector header design with internal baffles provides circuiting flexibility while eliminating the need for return bends, while the splayed header design uses return bends for circuiting in lieu of a collection header. The term “splayed” means that the coil headers are offset outward from the coil tubes. The splayed header coil always has same end connections.

Features

- Coil tubes are .020 copper.

- Coil Rows (2).

- Fins are made from .0075 Aluminum.

- Casing, Galvanized Steel.

- Connections, MPT Carbon Steel.

- Vents and drains are standard on all coils.

HOT WATER COIL MODULE

This Modular Hot Water Coil housing has been designed so that there is easy access to either side of the coil. Over sized doors offer plenty of room through which to clean and maintain the coil from either side of the housing. Blank off plates secure the coil and help maintain velocity across the coil. Modular design also lends its self to easier installations since modules bolt together on location. Heating applications are most commonly used in hot fluid systems for comfort conditioning of a forced air stream and in process systems for drying processes. The collector header design with internal baffles provides circuiting flexibility while eliminating the need for return bends, while the splayed header design uses return bends for circuiting in lieu of a collection header. The term “splayed” means that the coil headers are offset outward from the coil tubes. The splayed header coil always has same end connections.

Features

- Easy access to both sides of the coil making maintenance on the coil easier.

- Fully removable access doors on both sides of the housing.

- Coil connections protrude from the housing making installation easier.

- Housing constructed from G90 galvanized steel.

- Blank off plates secure the coil and maintain velocities.

- Easy bolt together modular design allows you to improve installation times, modules are smaller and lighter than standard all in one units.

- Coil tubes are .020 copper.

- Coil Rows (4).

- Fin are made from .0075 Aluminum.

- Casing, Galvanized Steel.

- Connections, 2.5 or 3.0" MPT Carbon Steel.

- Vents and drains are standard on all coils.

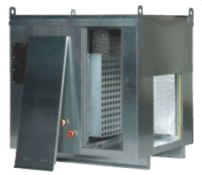

INDIRECT FIRED BENT TUBE MODULE

Providing clean and tempered makeup air to meet your application needs. The push-through design ensures that combustion fumes will not enter the fresh air stream.

The Modular Indirect Fired Bent Module is designed to deliver clean air into an indoor environment. The IBT heater module is approved in the United States and Canada. The unit is listed to the ANSI Z83.8-2006 and CSA 2.6-2006 standards. Each furnace has a 6:1 Turndown Ratio and a maximum Turndown of 28:1 for the entire unit, depending on total required BTU Capacity and number of furnaces in the unit.

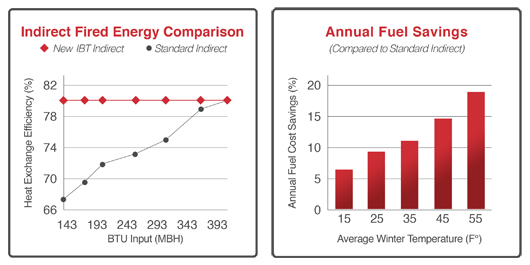

Every unit is programmed to start in high fire mode to ensure consistent light-off and is equipped with an electronic, Vernier-type fully-modulating control system. The duct furnaces are all type-409 stainless steel, and certified by the American Gas Association and approved by the Canadian Gas Association. Each model utilizes a single modulating stage, and between zero and three additional ON/OFF stages depending on the required heat output. In addition, the speed of its power-vent blower on the single modulating furnace is varied as the gas flow changes, thereby maintaining a constant 80% combustion efficiency over the entire gas-firing range of the unit.

Combination packages that include both exhaust and supply fans mounted on a single roof curb are also available; please contact your sales representative for more information.

Features

- Bent Tube In-Shot Style Furnace with Type 409 Stainless Steel Heat Exchanger

- 80% Constant Efficiency over Entire Gas Firing Range

- 6:1 Turndown per Furnace, 28:1 Max

- Full Electronic Vernier-type Modulation

- Forced High Fire Start

- Variable Speed Power-vent Motor

- Discharge, Space or Building Automation System (BAS) Temperature Control

- Isolated and Insulated Electrical Controls Vestibule

- Natural Gas or Liquid Propane Applications

- Inlet and Manifold Gas Pressure Indicating Gauges

- Electronic Push Button adjustment for the Modulating Gas Valve

- High Temperature Limit Switch

- Flame Rollout Switch with Manual Reset

- LED Indicators for Troubleshooting

- Economizer Inlet Air Thermostat

Options

- 5:1 Turndown for Propane (LP) per Furnace. 23:1 Max

- Up Discharge

- Motorized Intake Damper

- Remote Control Panel

- High and Low Gas Pressure Switch

- Mixing Box

- Variable Air Volume (VAV) Controls

- Double Wall Construction

- Blower on Delay (Heat Exchanger Pre-heat)

- Freeze-stat Option

- Fire-stat Option

- Convenience Outlet

- Extended Drop

- Single Point Electrical Connection

- Control Cabinet Heater

- Dirty Filter Airflow Switch

- Auxiliary Starters

- Roof Curbs

- Indoor Hanging Cradle

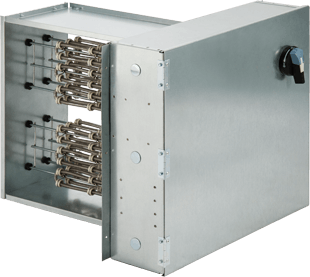

MODULATING ELECTRIC COIL

SCR Controlled Electric Coil

Electric Heat Coils are used in modular housings or in ductwork applications. Electric heat coils are used for tempering make-up air for installations requiring frequent air changes. The units are rated up to 257KW with voltages and phases to meet all electrical requirements. Air volume range is 400 – 22,000 CFM and up to 3″ wg @ standard air density, depending on the heating requirements. The heaters are intended for indoor or outdoor installations in commercial kitchens, factories, foundries and similar commercial and industrial occupancies.

Features

- SCR with modulating control.

- Redundant safety controls.

- Airflow proving switch.

- Temperature control system.

- High temperature limit.

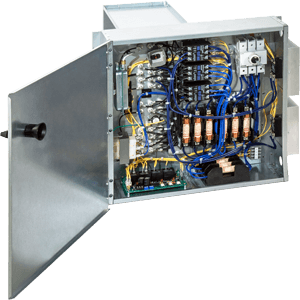

MODULATING ELECTRIC HEAT MODULE

This Electric Heat Module has been designed so that there is easy access to either side of the electric coil. Over sized doors offer plenty of room to clean and maintain the electric coil from either side of the housing. The modular design lends itself to an easier installation since modules bolt together on the jobsite location. Electric heater modules are used for tempering make-up air for installations requiring frequent air changes. The units are rated up to 257KW with voltages and phases to meet all electrical requirements. Air volume range is 400 – 22,000 CFM up to 3″ wg @ standard air density, depending on heating requirements. The heaters are intended for indoor or outdoor installations in commercial kitchens, factories, foundries and similar commercial and industrial occupancies.

Features

- G90 Galvanized steel.

- Modular design.

- SCR with modulating control.

- 120 volt control transformer, with single point electrical connection.

- Controls for stand alone or integrated operations.

- Electric coil safety equipment.

- Insulated housing.

- Access doors on both sides of the unit.

- Lifting points.

- Airflow proving switch.

- Temperature control system.

- Coil observation port.

- High temperature limit.

STAGED ELECTRIC COIL

Electric Heat Coils are used in modular housings or in ductwork applications. Electric heat coils are used for tempering make up air for installations requiring frequent air changes. The units are rated from 10 to 235KW and from 400 to 22,000 CFM’s, depending on heating requirements. The heaters are intended for indoor or outdoor installations in commercial kitchens, factories, foundries and similar commercial and industrial occupancies.

Features

- Staged heating control.

- Redundant safety controls.

- Airflow proving switch.

- Temperature control system.

- High temperature limit.

STEAM COIL

Uniform steam distribution to each of the coil core tubes is accomplished by proper header assembly design. The steam supply connection should be located in the center of the header, with a perforated plate type baffle located directly behind this connection. Properly sized orifices are located in each of the core tube entrances into the header.

Coils are “freeze resistant”, also known as the dual-tube design. It is important to note that any steam coil can freeze when exposed to freezing temperatures without the proper drainage of the condensate! This coil design utilizes a smaller inner tube, with precisely spaced, directional, orifice type perforations. This is to help direct condensate flow to the return header.

Features

- Max BTU’s 1,322,830

- Copper Coil Tubing

- Free floating coil core design to expand and contract in the casing

- 2 Coil Rows

- Galvanized Steel Coil Casing

- Copper Sweat Coil Connections

- Coil vents and drains

- .0075 aluminum fins

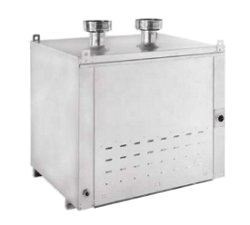

STEAM COIL MODULE

This Steam Coil housing has been designed so that there is easy access to either side of the coil. Over-sized doors offer plenty of room through which to clean and maintain the coil from either side of the housing. Blank off plates secure the coil and help maintain the proper velocity across the coil. The modular design all so lends its self to easier installations since modules bolt together on location.

Uniform steam distribution to each of the coil core tubes is accomplished by proper header assembly design. The steam supply connection should be located in the center of the header, with a perforated plate type baffle located directly behind this connection. Properly sized orifices are located in each of the core tube entrances into the header.

Coils are “freeze resistant”, also known as the dual-tube design. It is important to note that any steam coil can freeze when exposed to freezing temperatures without the proper drainage of the condensate! This coil design utilizes a smaller inner tube, with precisely spaced, directional, orifice type perforations. This is to help direct condensate flow to the return header.

Features

- Easy access to both sides of the coil making maintenance on the coil easier.

- Fully removable access doors on both sides of the housing.

- Coil connections protrude from the housing making installation easier.

- Housing constructed from G90 galvanized steel.

- Blank off plates secure the coil and maintain velocities.

- Max BTU’s 1,322,830

- Copper Coil Tubing

- Free floating coil core design to expand and contract in the casing.

- 2 Coil Rows

- Galvanized Steel Coil Casing

- Copper Sweat Coil Connections

- Coil vents and drains

- .0075 aluminum fins

Cart

- No products in the cart.